What should be pay attention to the installation of precision bearing

Precision bearing is mainly used in high-speed rotating occasions with light load, requiring high precision, high speed, low vibration and a certain service life of bearings.

It is often used as the supporting parts of high-speed motorized spindle in pairs. It is the hub fitting of high-speed motorized spindle of internal grinder.The service life of high-speed precision bearing is closely related to the installation. The following items should be pay attention to: 1. The bearing installation should be carried out in a clean room without dust. The bearing should be carefully selected and matched. The bearing spacer should be grinded. Under the condition of keeping the inner and outer spacer high, the parallelism of the spacer should be controlled below 1um.

2. the bearing shall be cleaned before installation. When cleaning, the inner ring slope shall be upward, and the hand induction shall be flexible without stagnation. After drying, put in the specified amount of grease. If it is oil mist lubrication, put in a small amount of oil mist oil;

3. special tools shall be used for bearing installation, with average stress and no knocking;

4. the bearing shall be stored in a clean and ventilated manner, free of corrosive gas, and the relative humidity shall not exceed 65%. Long term storage shall be rust proof on schedule.

In order to improve the actual matching accuracy of precision bearing installation, it is necessary to use the measuring methods and measuring tools that do not deform the precision bearing to carry out the actual precise measurement of the matching surface size of the inner hole and the outer circle of the precision bearing. The measurement items of the inner diameter and the outer diameter can be measured completely, and the measured data can be comprehensively analyzed. On this basis, the precision matching shaft and theThe size of the precision bearing installation part of the seat hole.When actually measuring the corresponding size and geometry of the matched shaft and seat hole, it should be carried out under the same temperature condition as when measuring the precision bearing.In order to ensure a high practical matching effect, the surface roughness of the matching surface between the shaft and the seat hole and the precision bearing should be as small as possible.When making the above measurement, two groups of marks shall be made on the outer circle and inner hole of precision bearing and the corresponding surface of shaft and seat hole on both sides close to the assembly chamfer to indicate the direction of maximum deviation, so as to align the maximum deviation of matching two sides with the same direction during actual assembly, so that the deviation of both sides can be partially offset after assembly.

The purpose of making two sets of directional marks is to comprehensively consider the compensation of the deviation. Even if the rotation accuracy of the two supports is improved, the coaxiality error between the two supports and the journal at both ends is partially eliminated.The surface strengthening measures, such as sand blasting, inserting the inner hole with a small diameter precision plug post and so on, can improve the matching accuracy.

For more information about bearings, please visit the official website, or consult our service hotline or wechat customer service.

The last:Zhenwei new DAC3570W-1CS72 hub bearing

Next up:What factors should be considered for bearing sealing

Product recommendations

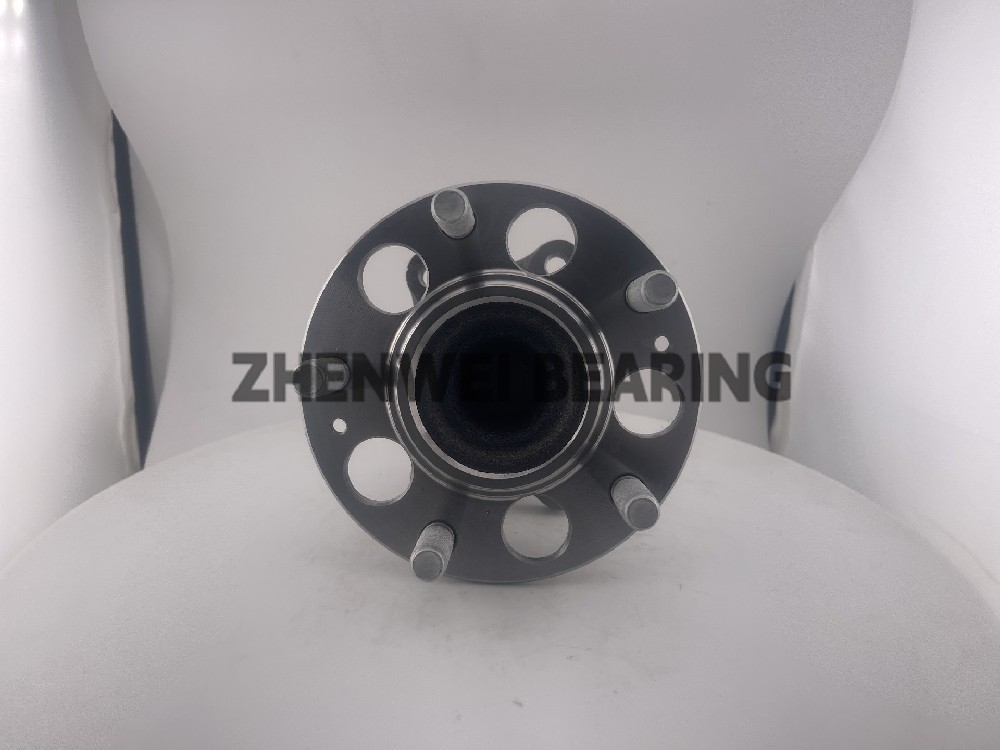

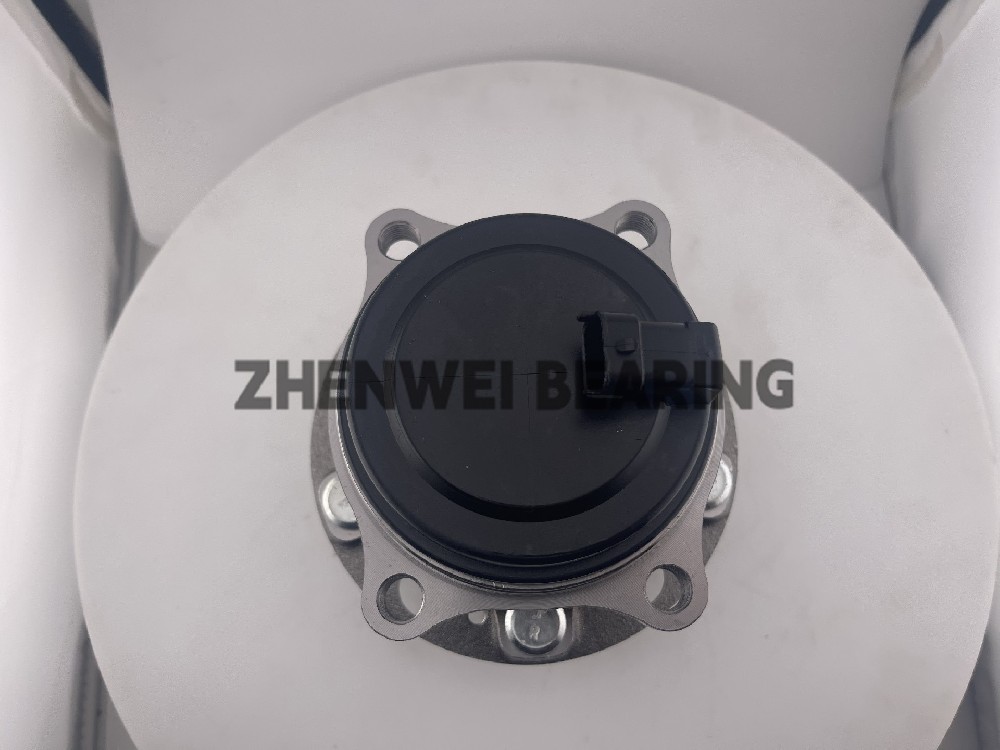

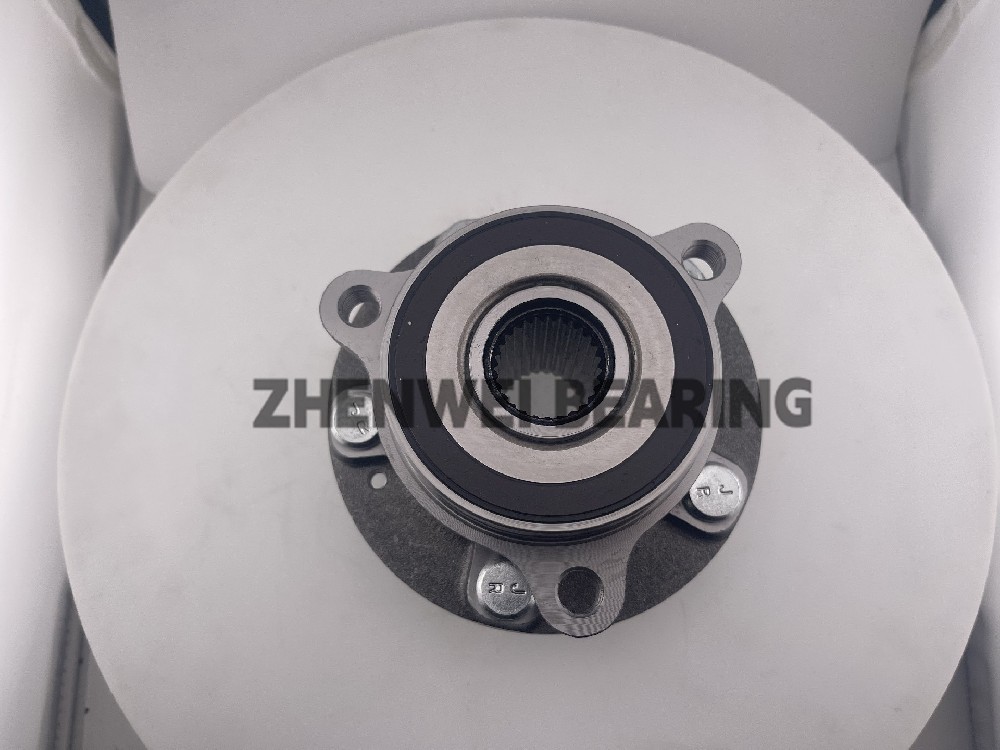

52730-Q6000 WHEEL HUB BE···

OEM NO.52730-Q6000Vehicle Model2019-2021 KIA SELTOSWhatsapp Number:+86 13711263563

52730-N9000 WHEEL HUB BE···

OEM NO.52730-N9000BR931190Vehicle Model2022- HYUNDAI TUCSONWhatsapp Number+86 13711263563

52730-K8000 WHEEL HUB BE···

OEM NO.52730-K8000Vehicle ModelHyundai Kia KX1Whatsapp Number+86 13711263563

52730-AAAA0 WHEEL HUB BE···

OEM NO.52730-AAAA0BR931184HA590905IJ113115WE62005Vehicle Model2020- ELANTRA/LANTRA/AVANTE Whats···

52720-S1000 WHEEL HUB BE···

OEM NO.52720-S1000BR931187WE62014IJ113114HA590907Vehicle Model2019-2023 HYUNDAI PALISADE 帕里斯帝&nb···

51750-S1000 WHEEL HUB BE···

OEM NO.51750-S1000513446WE62003BR931153IJ113104HA590906Vehicle Model2019-2023 HYUNDAI PALISADE2018-2···

51750-J9000 WHEEL HUB BE···

OEM NO.51750-J9000HA590804Vehicle Model2021-2024 KIA SeltosWhatsapp Number+86 13711263563

51750-B1600 WHEEL HUB B···

OEM NO.51750-B160051750-D2500IJ113090513419HA590774BR931116WE61900Vehicle Model2017-2020 HYUNDAI GEN···

51750-2J600 WHEEL HUB BE···

OEM NO.51750-2J600Vehicle Model2009-2015 KIA MOHAVE Whatsapp Number+86 13711263563

43550-11020 WHEEL HUB BE···

OEM NO.43550-110203DACF046F-2DSBR931119HA590765WE61936Vehicle Model2018- LEXUS LC500/LC500h2018- LEX···